| Availability: | |

|---|---|

| Quantity: | |

Samples:

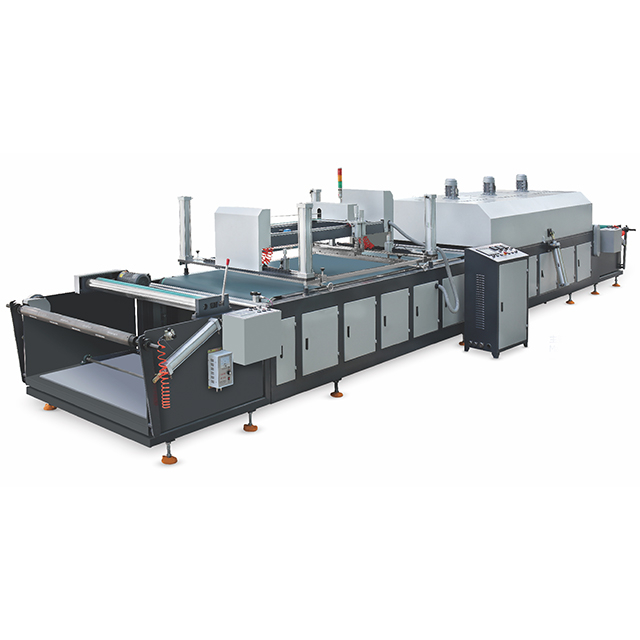

Type | HB-1200 |

Printing Color | One Color |

Max.Printing Speed | 20m/min |

Max.Printing Area | 1.1m*1.2m |

Workbench Dimension | 1.5m*1.35m |

Max.Screen Frame Dimension | 1.45m*1.35m |

Printing Material Thickness | 0.2-20mm |

Suitable Material | All coiled material |

Registration Accuracy | 2-5mm |

Printing Surface | Flat surface |

Overall Dimension (L*W*H) | 8.8m*1.62m*1.6m |

Power Supply | 380V |

Total Power | 20KW |

Weight | 2200KG |

Space Requirements | 12m*3m |

Product advantage

1.Automatic feeding,Printing,drying and receiving---saves manpower,to overcome the bound by weather conditions.

2.Balance pressure and thick ink layer---show your information better,suitable for high- grade non-woven products of printing.

3.Many kinds of printing plate net for your choice---insure the printing machine can be used more fully.

4.Large size of printing can printing multiple patterns at the same time---greatly improving the work efficiency.

5.The minimum interval of full size printing,between the effective patterns and the other effective patterns,can be up to 1 cm---effectively reducematerial loss.

6.The drive line system and overprint system of whole machine,PLC and servo motor control---ensure the printing accuracy.

7.Printing position precision and stability,can match with cut machine,cutting machine and non-woven bag making machine---greatly improve production efficiency.

8.It can be used in coiled material printing,such as non-woven,fabric,paper,leather,sticker, film and etc.

Samples:

Type | HB-1200 |

Printing Color | One Color |

Max.Printing Speed | 20m/min |

Max.Printing Area | 1.1m*1.2m |

Workbench Dimension | 1.5m*1.35m |

Max.Screen Frame Dimension | 1.45m*1.35m |

Printing Material Thickness | 0.2-20mm |

Suitable Material | All coiled material |

Registration Accuracy | 2-5mm |

Printing Surface | Flat surface |

Overall Dimension (L*W*H) | 8.8m*1.62m*1.6m |

Power Supply | 380V |

Total Power | 20KW |

Weight | 2200KG |

Space Requirements | 12m*3m |

Product advantage

1.Automatic feeding,Printing,drying and receiving---saves manpower,to overcome the bound by weather conditions.

2.Balance pressure and thick ink layer---show your information better,suitable for high- grade non-woven products of printing.

3.Many kinds of printing plate net for your choice---insure the printing machine can be used more fully.

4.Large size of printing can printing multiple patterns at the same time---greatly improving the work efficiency.

5.The minimum interval of full size printing,between the effective patterns and the other effective patterns,can be up to 1 cm---effectively reducematerial loss.

6.The drive line system and overprint system of whole machine,PLC and servo motor control---ensure the printing accuracy.

7.Printing position precision and stability,can match with cut machine,cutting machine and non-woven bag making machine---greatly improve production efficiency.

8.It can be used in coiled material printing,such as non-woven,fabric,paper,leather,sticker, film and etc.